In the intricate universe of heavy machinery, each constituent despite its seeming insignificance ensures that the machine operates efficiently and safely. Among these constituents, fan belts are unsung heroes which normally work behind the scene but significantly affect the performance of machines as well. They are usually made using tough materials so that they can keep some parts of a machine cool and in their optimal working conditions. A special component within this scope is komatsu pc210 fan belt; it is fashioned particularly for Komatsu PC210 machinery.

Komatsu, renowned globally, has always been at the forefront of innovation and quality in heavy machinery industry. This dedication is demonstrated by komatsu pc210 fan belt. The manufacturer designs it to fit Komatsu PC210 ensuring that the engine remains cool throughout hence preventing overheating risks and promoting consistency in terms of power output. While engaged in digging, building up or doing any other demanding task, komatsu pc210 fan belts help to lower down temperatures on engines such that all other moving parts may run perfectly without hitches.

As we navigate through this comprehensive guide, we will delve deeper into the features, installation procedures, maintenance tips and troubleshooting steps associated with the komatsu pc210 fan belt. This guide aims at providing operators/users/technicians of Komatsu PC210 with knowledge on how to make their fans last longer without damages that affect their functionality over time of use.

Key Features of the Komatsu PC210 Fan Belt

The komatsu pc210 fan belt is not just any ordinary belt; it’s a result of careful design, research and engineering adapted specifically for the Komatsu PC210 machinery. Some understanding of its main characteristics will give an idea about its importance and advantages. Let us now look at the material, design specifications as well as performance characteristics of this vital part.

Material and Design Specifications:

- High-Quality Material: The komatsu pc210 fan belt is made from a blend of synthetic rubber compounds in order to make them durable, flexible and resistant to wear. This material makes sure that the belt can withstand heavy operations and extreme environments associated with these machines.

- Reinforced Structure: There are high tensile strength cords embedded within the rubber compound to enhance its strength while reducing chances of stretching or snapping when under tension.

- Specially Grooved Design: This ensures that it grips the pulleys perfectly thereby reducing slippages and ensuring continuous power supply.

- Heat Resistance: Given its role in cooling and its proximity to the engine, this belt has been designed to resist heat ensuring that it does not degrade or lose integrity when it is hot.

- Oil and Contaminant Resistance: The materials used in designing this particular belt are oil-proof preventing accidental spills from compromising it or any other contaminant from destroying its functionality.

Durability and Performance Characteristics:

- Long Lifespan: Due to sturdy construction alongside high-quality materials used, komatsu pc210 fan belts are known for their longevity even under continuous strenuous use conditions. Consistent Tension: It provides consistent tension during entire operational cycle so that components such as engine parts supplied by the fan do not receive pulsating power impact. Minimal

- Vibration: consequently, low levels of vibration reduce wear on associated parts besides smoothening machine processes

- Efficient Power Transmission: It therefore leads to efficient transmission of power from engine through all the driving components thus enabling machinery work at optimal speed.

Finally, Komatsu PC210 fan belt is an engineering feat that was designed with precision to suit the needs and specifications of a Komatsu PC210 machine. Not only does its features guarantee proper cooling to the engine but it also enhances other machinery’s efficiency and lifespan.

Importance of the Fan Belt in the Komatsu PC210

The komatsu pc210 fan belt might seem like a simple component, but its role in the Komatsu PC210 machinery is paramount. It’s not just about transferring power; it’s about ensuring that the entire machinery operates harmoniously and efficiently. Let’s explore the significance of this fan belt in the context of the Komatsu PC210’s operations.

How the Komatsu PC210 Fan Belt Aids in Cooling and Engine Performance:

- Engine Cooling: The primary function of the komatsu pc210 fan belt is to drive the cooling fan, which in turn circulates air around the engine. This process ensures that the engine remains within its optimal temperature range, preventing overheating and potential damage.

- Optimal Power Transmission: The fan belt ensures that power from the engine is efficiently transmitted to various components, such as the alternator, water pump, and air conditioning compressor. This seamless power transmission ensures that all these components work in harmony, contributing to the overall performance of the machinery.

- Preventing Overheating: In the absence of an effective fan belt, the risk of the engine overheating increases manifold. Overheating can lead to engine damage, reduced efficiency, and even complete machinery breakdowns. The komatsu pc210 fan belt plays a crucial role in preventing such scenarios.

The Relationship Between the Fan Belt and Other Engine Components:

- Synchronized Operations: The fan belt ensures that components like the alternator, which charges the battery, and the water pump, which circulates coolant, operate synchronously with the engine’s rhythm. This synchronization is vital for the smooth functioning of the Komatsu PC210.

- Reduced Wear and Tear: By ensuring consistent tension and efficient power transmission, the komatsu pc210 fan belt reduces the wear and tear on associated pulleys and components. This not only prolongs the life of these components but also reduces maintenance costs.

- Safety and Protection: A well-maintained fan belt acts as a safeguard, preventing potential hazards like engine overheating. It ensures that the machinery remains safe for operators and reduces the risk of unexpected downtimes.

In essence, the komatsu pc210 fan belt is like the unsung hero of the Komatsu PC210 machinery. While it might not be as prominent as some of the larger components, its role is undeniably crucial. It ensures that the engine remains cool, that power is efficiently transmitted to various components, and that the machinery operates at its peak efficiency. Recognizing its importance is the first step in ensuring its proper maintenance and care.

Installation Tips for the Komatsu PC210 Fan Belt

Installing the komatsu pc210 fan belt correctly is crucial for ensuring the optimal performance and longevity of both the belt and the machinery. A poorly installed fan belt can lead to inefficiencies, increased wear, and even potential damage to associated components. Here are some pre-installation checks, a step-by-step guide, and tips to ensure proper tension and alignment during the installation process.

Pre-installation Checks and Preparations:

- Inspect the New Belt: Before installation, inspect the new komatsu pc210 fan belt for any visible defects, cracks, or deformities. Ensure that it matches the specifications of the old belt.

- Check Associated Components: Inspect pulleys, tensioners, and other components that the belt interacts with. Ensure they are clean, free from damage, and aligned correctly.

- Gather Necessary Tools: Ensure you have all the necessary tools at hand, including wrenches, a tension gauge, and safety gear like gloves and safety glasses.

Step-by-Step Guide to Installing the Komatsu PC210 Fan Belt:

- Safety First: Before starting, ensure the machinery is turned off, the key is removed, and you’re wearing appropriate safety gear.

- Loosen the Tensioner: Locate the belt tensioner and loosen it to provide enough slack to remove the old belt.

- Remove the Old Belt: Carefully slide the old belt off the pulleys, noting its routing. It’s helpful to take a photo or sketch the routing for reference during the installation of the new belt.

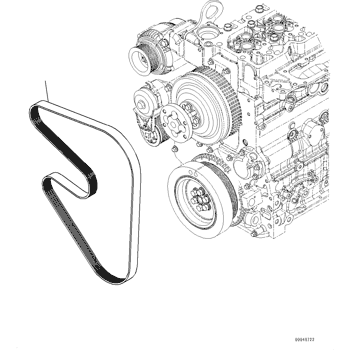

- Install the New Belt: Using the reference from the previous step, route the new komatsu pc210 fan belt around the pulleys. Ensure it sits correctly in the grooves and is not twisted.

- Adjust the Tension: Tighten the tensioner until the belt has the recommended tension. Too tight can cause excessive wear, while too loose can lead to slippage.

- Double-Check: Once installed, rotate the main pulley several times to ensure the belt is seated correctly and maintains consistent tension.

- Start the Machinery: Turn on the Komatsu PC210 and let it run for a few minutes. Observe the belt’s movement to ensure it operates smoothly without any wobbling or misalignment.

Ensuring Proper Tension and Alignment:

- Use a Tension Gauge: For precise tension adjustments, use a tension gauge. This ensures that the belt is neither too tight nor too loose.

- Check Alignment: The belt should run parallel to the pulleys. Misalignment can cause uneven wear and reduce the belt’s lifespan.

- Regularly Monitor: Especially during the initial days after installation, regularly check the belt’s tension and alignment. This helps in early detection of any potential issues.

In conclusion, while the installation of the komatsu pc210 fan belt might seem straightforward, attention to detail is crucial. Proper installation ensures that the belt serves its purpose effectively, ensuring the smooth operation of the Komatsu PC210 machinery.

Maintenance and Care for the Fan Belt

The komatsu pc210 fan belt, while designed for durability and consistent performance, requires regular maintenance to ensure its longevity and optimal functioning. Proper care not only extends the belt’s lifespan but also ensures that the Komatsu PC210 machinery operates efficiently. Here are some routine inspection and cleaning procedures tailored for the komatsu pc210 fan belt, along with tips to prolong its life.

Routine Inspection and Cleaning Procedures:

- Visual Inspection: At regular intervals, inspect the komatsu pc210 fan belt for signs of wear, such as cracks, fraying, or glazing. Early detection of these signs can prevent potential breakdowns.

- Check for Proper Tension: Over time, the belt may lose its tension, leading to inefficiencies or slippage. Ensure that the belt maintains the recommended tension. Adjust if necessary.

- Clean the Belt: Dust, debris, and contaminants can reduce the belt’s grip and cause premature wear. Use a clean cloth to wipe down the belt and remove any accumulated dirt.

- Inspect Pulleys and Tensioners: The health of associated components directly impacts the belt’s performance. Check pulleys for alignment and wear. Ensure that tensioners function correctly and maintain consistent tension on the belt.

- Listen for Noises: Unusual noises, such as squealing or chirping, can indicate issues with the belt or associated components. Investigate and address the root cause if such sounds are detected.

Tips for Prolonging the Lifespan of the Belt:

- Avoid Contaminants: Exposure to oils, coolants, or other chemicals can degrade the belt’s material. Ensure that the belt is protected from such contaminants.

- Maintain Optimal Tension: Consistently maintaining the recommended tension ensures that the komatsu pc210 fan belt operates efficiently and reduces wear.

- Use Genuine Replacements: If the belt requires replacement, always opt for genuine komatsu pc210 fan belt replacements. Genuine belts are designed to meet the specific requirements of the Komatsu PC210 machinery, ensuring compatibility and performance.

- Regularly Service the Machinery: Regular servicing of the Komatsu PC210 ensures that all components, including the fan belt, are in optimal condition. This holistic approach to maintenance can significantly extend the belt’s lifespan.

- Stay Informed: Stay updated with any manufacturer recommendations or updates regarding the komatsu pc210 fan belt. This ensures that you’re always following the best practices for maintenance and care.

In conclusion, the komatsu pc210 fan belt is a vital component that demands regular attention and care. By adopting a proactive approach to maintenance, operators can ensure the belt’s longevity and the consistent performance of the Komatsu PC210 machinery.

Troubleshooting Common Issues

The komatsu pc210 fan belt is like all other machinery components which can have faults after some time specifically if they are exposed to the extreme environments or the regular checkups are not made. Before one realizes, any window for early arising issues could become a more serious complication in the future. This section will discuss common problems associated with komatsu pc210 fan belts and give suggestions and remedies.

Recognizing Signs of Wear and Potential Problems:

- Squealing or Chirping Noises: A high-pitched scream or tweet while the engine is running usually means a loose or worn-out fan belt. The noise comes from slipping on pulleys by a belt.

- Visible Cracks or Frays: At normal intervals, look at the presence of cracks, frays or glaze on your belt as they show that they are becoming weak enough to break eventually.

- Vibration: Excessive vibration when an engine is running may indicate that komatsu pc210 fan belt is improperly installed or misaligned.

- Overheating Engine: When the cooling system fails this means that it may be as a result of malfunctioning belt leading to poor cooling and thus an engine can overheat.

Solutions and Fixes for Common Fan Belt Issues:

- Tighten or Replace the Belt: If you hear squealing noises caused by a loose belt try tightening it by adjusting tensioner. If your belt is old and have any signs of use then think about replacing it completely.

- Check Pulley Alignment: The pulleys which are not aligned well can lead to irregular wearing out of belts or even slipping off them. It’s important to ensure all pulleys are properly aligned without any damage on them.

- Clean the Belt and Pulleys: Dirt, moisture/oil etc., reduce grip between pulley surface and belts. Use mild detergent with water cleaning it plus make sure there isn’t contamination present here

- Replace Damaged Components: In case you observe problems such as damaged pulleys, tensioners or any other associated components, make sure you change them. Belt performance can be affected by damaged parts.

- Regular Inspections: Be proactive and conduct regular checks on the komatsu pc210 fan belt as well as other linked components. Early detection of potential issues can prevent more significant problems and downtimes.

- Consult the Manual: Troubleshooting steps are provided in detail in Komatsu PC210’s user manual for specific machinery. Should you experience a problem that is not addressed here; find time to look at your manual or talk to Komatsu technician.

In essence, even though this komatsu pc210 fan belt is built for long-lasting service, it may still wear out and develop some issues with time. However, by conducting inspections from time to time, intervening promptly and following suggested servicing schedules most of these common issues can be resolved effectively ensuring that Komatsu PC210 works perfectly.

When to Replace the Komatsu PC210 Fan Belt

The komatsu pc210 fan belt is a vital component in ensuring the smooth operation of the Komatsu PC210 machinery. However, like all parts, it has a finite lifespan and will eventually require replacement. Recognizing the right time to replace the belt is crucial to prevent potential downtimes and maintain the machinery’s efficiency. Here, we’ll explore the indicators of wear and the importance of using genuine replacements.

Understanding Wear Indicators and Assessing Belt Condition:

- Visible Signs of Wear: The komatsu pc210 fan belt should be regularly checked for visible signs such as cracks, frays or glazing; these demonstrate that material constituting this very useful item is deteriorating, rendering it less useful over time.

- Unusual Noises: Often when you come in contact with belts producing sound such as squealing, chirping among others that are not common they are loose, misaligned or worn out.

- Slippage: It may be an indication that your engine may experience overheating or other components could malfunction regularly if you have a belt which slips often.

- Age: Sometimes your belt may not show obvious signs of wear but its age can affect how well it functions. For instance; rubber and other materials break down over time hence if the belt is several years old consider changing it to be safe than sorry.

- Frequent Adjustments: When there are frequent adjustments made of tension or alignment related to the belt then its elasticity might be going away or even its strength meaning that one needs another one.

Importance of Using Genuine Komatsu OEM Parts for Replacements:

- Perfect Fit: The authentic komatsu pc210 fan belt replacements match perfectly with Komatsu PC210 machines leading to their good performance at all times especially during working hours respectively

- Quality Assurance: In order to meet company’s desired standard requirements stringent test and quality checks on Komatsu’s OEM parts must always undertaken by them inclusive

- Longevity: Manufactured from good materials, real parts are expected to last longer and deliver uniform performance at any given time

- Warranty and Support: There are times using authentic pieces comes with other added merit of warranty coverage in case anything happens or support from Komatsu which brings a sense of peace to equipment operators and owners.

- Optimal Performance: Consequently, the entire system will be more effective, if we install genuine fan belts into it. The probability of future failures or downtimes will decline accordingly.

In conclusion, while the komatsu pc210 fan belt is designed for durability, it’s essential to recognize when it requires replacement. Timely replacements, coupled with the use of genuine parts, ensure that the Komatsu PC210 machinery continues to operate efficiently, safely, and reliably.

The fan belt of the Komatsu PC210 is a complex element that shows how detailed and elaborate heavy machinery components can be. Although it might seem like a simple part, its importance in maintaining smoothness and efficiency of the Komatsu PC210 cannot be underestimated. This belt lies at the heart of the machine’s performance, from cooling down the engine to driving essential parts.

Consequently, it is critical that one carries out regular maintenance while doing timely troubleshooting and knows when to replace it so as to keep both the belt and machine running at their best. Furthermore, going for genuine komatsu pc210 fan belt replacements means that there will be quality since they are designed by professional Komatsu engineers.

Finally, just as with all other heavy machines, Komatsu PC 210 is an integration of components working in coordination with each other where none can operate without another component being functional. And this humble fan belt has a major contribution to make in this symphony. Paying attention to its needs shall enable operators or technicians maintain uniformity of operation across all times thereby making it more cost-effective and consistent during discharge of their functions.

References and Further Reading

- Komatsu Official Manuals: Komatsu’s official manuals and technical guides offer in-depth information on installation, maintenance, and troubleshooting for all their machinery components, including the pc210 fan belt.

- “Heavy Machinery Maintenance” by James T. Henderson: This book provides a comprehensive overview of the maintenance practices for heavy machinery, touching upon the importance of components like fan belts.

- “The Science of Engine Cooling” by Dr. Alan R. Smith: A deep dive into the principles of engine cooling, this resource sheds light on the pivotal role fan belts play in the process.

- Komatsu Technical Workshops: Komatsu often conducts workshops and training sessions for technicians and operators. These sessions can provide hands-on experience and insights into the maintenance and care of components like the pc210 fan belt.

- Online Forums and Communities: Websites like HeavyEquipmentForums.com and MachineryZone have dedicated sections for Komatsu machinery, where operators and technicians share their experiences, tips, and solutions related to various components.

- “Belt Drive Systems: Design and Maintenance” by Richard P. Brown: This book offers a detailed look into the design principles and maintenance practices for belt drive systems, providing valuable insights for those looking to understand the intricacies of fan belts.