In the realm of heavy machinery, where power and performance are paramount, even the simplest looking components have a vital role in ensuring that equipment keeps operating smoothly. One of these is the fan belt which does not get the limelight but remains very vital to the heart of heavy machinery and engine cooling.

The purpose of a fan belt is simple yet indispensable. It connects the engine’s crankshaft and cooling fan allowing the fan to allow circulating air through the radiator thus dissipating heat generated during running of an engine. This cooling process is necessary for preventing overheating and maintaining an optimum working temperature for engines.

The importance of the function carried out by a fan belt is far more than just keeping an engine cool. A properly functioning fan belt ensures that an engine runs within its desired temperature range, thus optimizing it for longer life as well as greater efficiency. When running too hot, this increases risk not only leading to reduced performance but also possible damage to major parts.

It might seem like choosing a right fan belt is not such a big deal, but this could make or break any machine’s lifetime along with its overall performance. For instance, one such belt that has been designed, manufactured as well as tested to meet strict exigencies imposed by heavy plant would ensure that equipment can be relied on while still producing at high levels and at low costs.

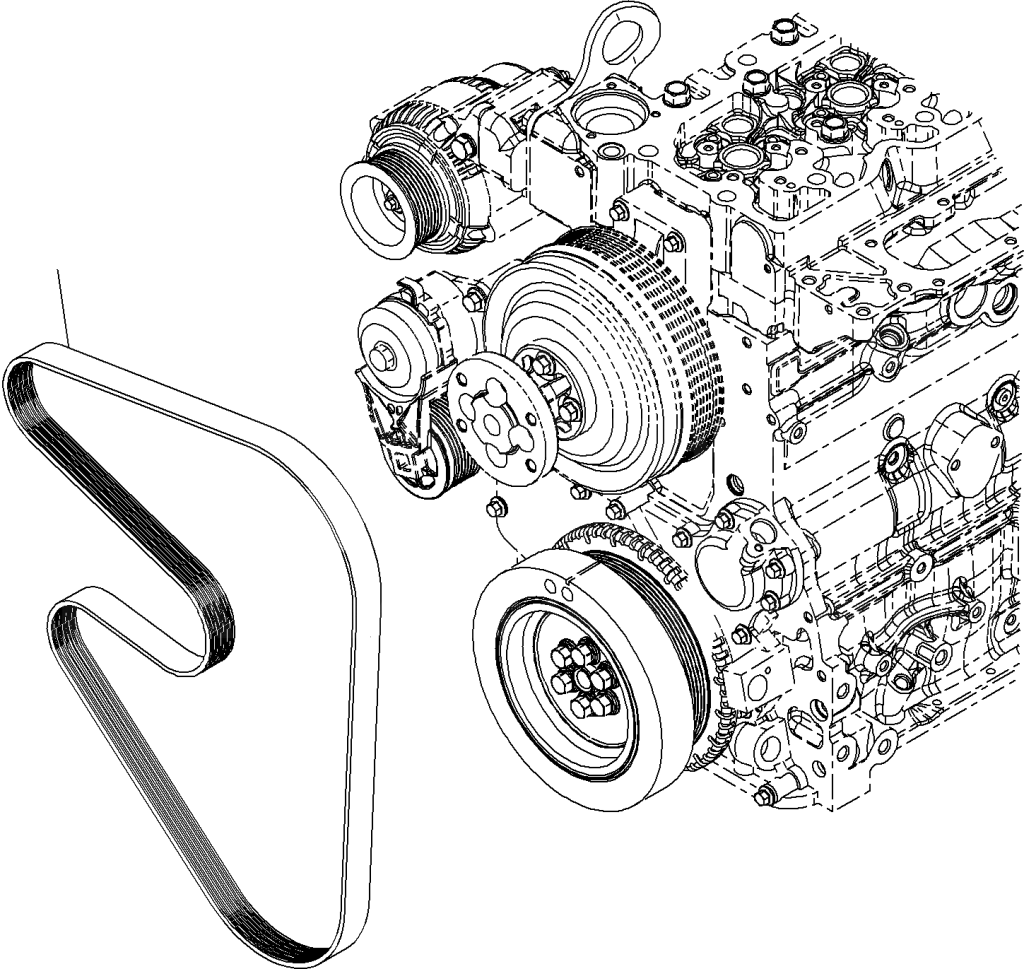

As we go further into examining different types of fan belts particularly genuine Komatsu PC200 fan belt from recognized brand in heavy industry, we shall then explore how this particular type helps improve optimal machinery operation through proper choices made when selecting them which may appear small though they are fundamental accessories.

Understanding the Genuine Komatsu PC200 Fan Belt

The Genuine Komatsu PC200 Fan Belt is a reliable piece of engineering in the world of heavy machinery characterized by precision and dependability. To understand it fully, let us look into the intricacies of this important part.

About Komatsu: A Leading Brand in Heavy Machinery:

Before we go any further into the fan belt itself, it is important to recognize its manufacturer-Komatsu. Komatsu enjoys global recognition as an industry producer of heavy machinery that underpins industries worldwide. Their dedication to quality, innovation and performance have won them trust among operators, contractors and industry experts.

Detailed Specifications and Design Features:

This belt is engineered for heavy machinery like Komatsu PC200. It has several specifications and design features which include:

- Quality Material: The fan belt is made using high quality materials chosen due to their toughness and durability that provide strength against any kind of pressure over time.

- Precise Dimensions: Each fan belt comes with accurate measurements to ensure proper compatibility with engine compartments in machines. Fitment must be done appropriately for one’s machine to perform well over a long period.

- Advanced Design: The PC200 fan belt has been designed through extensive research and development efforts. In order to enhance efficiency, reduce friction losses during power transmission from an engine crankshaft towards cooling fans; the alternator belts are engineered accordingly.

- Quality Assurance: Nothing shakes their commitment to quality at all! Every single fan belt undergoes comprehensive tests so as to meet or even exceed industry benchmarks; guaranteeing operators as well as fitters on its capability.

Impact on Engine Cooling and Overall Machinery Performance:

There’s no doubt that the importance of fan belt in engine cooling cannot be understated. It ensures that the cooling fan operates thereby maintaining an optimum running temperature for an engine. An efficient engine runs within acceptable temperatures leading lower levels of wear out.

These are some ways by which perfect construction combined with preciseness can make sure that this role is carried out efficiently by Komatsu PC200 Fan Belt. Also, in the prevention of overheating and hence safeguarding of the engine performance by effectively circulating air through a radiator.

In the heavy machinery industry, where downtime can be costly and safety is paramount, the Genuine Komatsu PC200 Fan Belt emerges as a reliable choice. It is compatible with Komatsu machines while its history of superior performance has made it popular with experts who prefer nothing but the best for their equipment.

The Benefits of Choosing Genuine Komatsu PC200 Fan Belts

Every element matters, however small it may be, when it comes to ensuring the peak performance and durability of heavy machinery. In this case, selection of a fan belt may significantly impact overall efficiency as well as reliability of the equipment at large. Let’s outline some tangible advantages of using genuine Komatsu PC200 Fan Belt for your heavy duty needs.

Reliability and Durability:

One of the key benefits that accompany choosing original Komatsu fan belts is their unmatched dependability and durability. These fan belts are made to withstand the toughest operating conditions and built to last. This implies that they can be used in heavy machinery activities without compromising on their integrity since they are constructed with quality materials.

Effect on Engine Cooling:

Efficient engine cooling is necessary in order to maintain optimum performance of any machine. Specifically tailored for smooth operation of the cooling fans, Komatsu PC200 Fan Belt guarantees that its application always runs smoothly. The radiator passes air by way of convection ensuring rapid cooling while dissipating heat produced during functioning of an engine with ease. Consequently, engines that work within their preferred temperature ranges not only perform better but also wear less hence have longer useful lives.

Assurance of Compatibility and Quality:

The decision to choose genuine Komatsu fan belts further offers operators as well as technicians a guarantee on compatibility and quality issues. These fan belts were designed so as to perfectly fit into Komatsu machines thereby providing users with proper functioning devices through seamless integration processes. It is extremely important for effective working conditions as well as safety in heavy machinery applications.

Besides, there is no compromise over quality by Komatsu Company .Each belt undergoes rigorous checks targeting industry standards before or rather during production which enhances confidence among end users regarding reliable services from these products.

Improved Machinery Efficiency:

Fan belt choice has direct implications on machinery efficiency that has high value for manufacturers who deal with heavy-duty machineries like vehicles involved in earth-moving activities. Genuine Komatsu fan belts are engineered to minimize friction and enhance the smooth flow of power from an engine’s crankshaft to a cooling fan. As a result, this reduces energy loses that could have occurred making the machine work at its best performance which is really economical in terms of cost savings offering better production.

Long-term Cost Savings:

Genuine Komatsu fan belts may be more expensive when compared to non-genuine alternatives but they create long-term cost savings. Since they are durable and reliable, fewer replacements, reduced downtime and lower maintenance costs would be incurred during the life span of these machines. Therefore their purchase can be seen as a good investment by any organization ready to get maximum output while operating heavy machinery.

In conclusion, the advantages of selecting genuine Komatsu PC200 Fan Belts go beyond immediate benefits .These include reliability and durability, compatibility and improved machinery efficiency all which contribute to overall performance and cost-effectiveness in heavy machinery operations. When it comes to preserving your machinery’s operation and maintaining its lifespan, choosing a fan belt is indeed an extremely vital decision.

Real-world Case Studies: Improved Performance with Genuine Fan Belts

In order to demonstrate the benefits of using real Komatsu PC200 Fan Belts, let us examine actual case studies that spotlight the concrete improvements seen in machine performance when these first-rate elements are used.

Case Study 1: Improved Efficiency during Excavation

In one massive excavation project involving plenty of Komatsu excavators, there was a decision of swapping fan belts with genuine Komatsu PC200 Fan Belts. The excavators were operating continuously under tough climatic conditions characterized by high temperatures and dust quantities. There were some noticeable outcomes once this operation was complete:

- Enhanced Cooling Efficiency: Even during extreme situations, the original Komatsu fans guaranteed reliable and effective cooling system. As such, this resulted in significant decrease in engine overheating cases enabling the machines to run at their maximum capacity for longer periods.

- Fuel Savings: Because of better engine performance, fuel consumption by the excavators reduced without affecting their functionality. This led to considerable savings on fuel expenses throughout the entire duration of the construction.

- Extended Maintenance Intervals: Less frequent replacements due to sturdy fan belts translated into decreased downtime for maintenance purposes leading to increased productivity of projects as well as saving on costs associated with maintenance services.

Case Study 2: Dependable Performance while Mining

The fan belts were considered as one of critical components affecting engine performance in a mining operation which had numerous dump trucks from Komatsu Company. Genuine Komatsu PC200 Fan Belts were picked out based on factors like dependability and durability. What emerged as a result is worth noting:

- Consistent Performance: The fan belts provided steady engine cooling even at harsh mining conditions. Thus, this leads to uninterrupted operations hence more efficient hauling of ore.

- Reduced Wear and Tear: The radiator and water pump among other engine parts wore out less because there was stable cooling brought about by the fan belts hence extending lives of such components and reducing costs associated with maintaining them.

- Safety Assurance: It could be extremely hard to fix breakdowns at the mining site, which was in a remote region. In this case, the genuine fan belts were utilized as an additional layer of safety and reliability thereby minimizing any chances for unexpected equipment failures.

These practical examples indicate how important it is to use real Komatsu PC200 Fan Belts in heavy machinery operations. Continuous improvement in cooling efficiency, fuel savings, longer maintenance periods and overall machine dependability provide strong proof why quality fan belts are necessary in heavy machinery. Thus when buying a fan belt for your heavy machinery be mindful that doing so is an investment into long-term success especially when you consider both performance and cost-effectiveness factors.

Maintenance and Care for Fan Belts

In order to keep your heavy machines working optimally and serve you for a long time, such as Komatsu PC200, one should learn how to maintain its crucial parts including the fan belt. A properly maintained fan belt guarantees effective cooling of the engine and continuous operation of the equipment. Below are some critical care and maintenance tips for your Komatsu PC200 Fan Belt:

Routine Inspection:

Periodic visual inspections help in early detection of any signs of wear, damage or misalignment on the fan belt. Check if there are any cracks on the surface, fraying or glazing that may necessitate replacement. Furthermore, ensure that there is proper tension and alignment since loose belts or misaligned ones can result into inefficient operation as well as early wearing.

Cleaning:

Dirt and other debris can settle on top of the fan belt thereby reducing its efficiency or even causing damages. From time to time, use a soft brush or cloth to get rid of any contaminants from it. Do not use abrasive materials that would destroy its surface.

Tension and Alignment:

Fan belt’s performance depends upon correct tensioning and alignment. For recommended tension specifications refer to manufacturer’s guidelines or your machinery’s manual while carrying out adjustments. Over tightening or loosening may cause problems such as; slipping off, too much tear and reduced cooling efficacy.

Replacement Interval:

Even with regular maintenance, all fan belts have their lifespan after which they will need replacement eventually. Based on factors like usage conditions among others follow manufacturers recommended interval for replacement which varies accordingly. It is important to have spare fan belts so that in case of unexpected failures you can minimize downtime.

Use Genuine Komatsu Replacement Belts:

Whenever it comes to replacing it always go for genuine Komatsu PC200 Fan Belts only . Genuine parts fit perfectly with each other because they were designed to exact specifications resulting in compatibility between them hence optimal performance . They also meet and even surpass industry standards due to their strict quality control hence users are assured of their reliability and durability .

Safety Precautions:

When working on heavy machinery, safety must be a priority. Before engaging in any maintenance work on the fan belt, make sure that the equipment is off and all residual energy has dissipated. Always follow safety rules and put on proper personal protective equipment in particular when dealing with machine parts.

Professional Maintenance:

For complicated maintenance operations or replacing belts, it is better to involve qualified technicians or professionals with enough experience of maintaining heavy machines. They will ensure correct installation of a fan belt as well as its optimal performance depending on their knowledge acquired over time.

By following these guidelines for maintenance and care, you can extend the life of your Komatsu PC200 Fan Belt as well as increase its usefulness. Regular inspections, cleaning, appropriate tensioning, and timely replacement with genuine Komatsu parts are important steps towards ensuring effective operation of your heavy machinery within a long period of use.

Challenges and Risks of Using Non-Genuine Fan Belts

The use of non-genuine fan belts in heavy machinery can pose significant challenges and risks. To enable you to make informed decisions about your equipment, it is important that you understand these risks. The following are some of the common challenges and dangers associated with using non-genuine fan belts:

Reduced Dependability:

Non-genuine fan belts may not meet the same quality standards and specifications as genuine parts, leading to reduced dependability and durability, resulting in unexpected failures and down time for your machinery.

Compatibility Issues:

It may be difficult for non-genuine fan belts to be designed accurately to fit onto your specific model of machine. Misfitting could result in misalignments, poor tensioning and lower engine cooling, which overall affect the operations of the machinery.

Ineffective Cooling:

Properly keeping cool an engine is facilitated by fan belts which play a critical role in this process; however they may not serve this purpose as efficiently as required by their function hence cause overheating hence leading to damage to the engine.

Increased Maintenance Costs:

Choosing non-genuine fan belts can result into increased maintenance expenditures over time. These types of parts also wear out more quickly thus necessitating some replacements more frequently than others do leading to machine downtime during repair work increasing functional cost incurred.

Safety Concerns:

When you try using counterfeit fan belts there are possible safety implications as unreliable ones might snap when least expected thereby causing injuries on operators or maintenance employees.

Warranty Voidance:

Equipment manufacturers such as Komatsu offer warranty coverage for their machines if original products are utilized while using counterfeit components would mean that you have no warranty cover so any expenses incurred on repairs or replacements are borne by you.

Reduced Resale Value:

In future, if you intend to sell or trade-in your equipment then it’s worth noting that use of counterfeit will negatively affect its resale value since buyers prefer those with records of using genuine parts due to their assurance in terms of quality and reliability.

Legal and Compliance Issues:

Using non-genuine fan belts may raise legal and compliance concerns under some circumstances. Regulatory standards can be violated through counterfeit parts which may lead to legal implications for such actions as infringement of intellectual property rights.

Unknown Origins:

Information regarding the origin of manufacturing and materials used in making non-genuine fan belts is not widely available, hence, it is difficult to know their quality or reliability.

In conclusion, while non-genuine fan belts may appear cost-effective at first, they have numerous challenges and risks that can finally influence performance, safety and total cost of operating heavy machinery. To ensure that your equipment performs at its best for as long as possible, it is recommended that you select authentic fan belts like Komatsu PC200 Fan Belt that are designed specifically for high-quality standards and reliable service provision. Genuine parts investment is a commitment made towards the success of your machinery in the long run.

The choice of parts in heavy machinery, which depends on reliability, performance and safety; is crucial for the best results. The Komatsu PC200 Fan Belt is simply one of those components that are very crucial in ensuring that heavy equipment works efficiently. As we have seen from our survey, there are several advantages derived from choosing the genuine fan belts.

Reliability and Durability: Genuine Komatsu PC200 Fan Belts bear exact specifications when engineered hence built with top quality materials through vigorous quality control. This commitment definitely guarantees exceptional durability and reliability for the fan belts. A genuine Komatsu fan belt would rise to the demands at peak periods when heavy machinery needs it most.

Optimized Cooling: Heavy machinery engines must be cooled down efficiently, not because it is a luxury but it’s necessary. Precise tolerance designed fan belts deliver optimized cooling performance. Thus, this leads to reduced risks of overheating, better engine operation efficiency and prolonged machinery existence.

Compatibility and Quality Assurance: When you choose a genuine Komatsu PC200 Fan Belt, you’re not merely selecting a component; you’re investing in a piece of your machine’s heart. It ensures proper alignment as well as tension by perfectly fitting into your Komatsu machine (fan belts). In addition, using original parts brings about an unmatched quality assurance unlike their non-genuine counterparts.

Real-world Results: Real world results speak louder than technical specifications or promises made by manufacturers. Numerous operators and machine owners have been able to find improved performance; fewer maintenance costs as well as extended life spans for their devices where they bought authentic fan belts instead of fake ones. These success stories are indicative if what you stand to gain.

In brutal conditions under which heavy machines operate today every part matters a lot.. The choice of a fan belt may seem trivial but don’t underestimate its impact on how your machines work especially how long they last Genuine Komatsu PC200 Fan Belts provide incredible level of quality, reliability and unbeatable performance.

While investing in heavy machinery, always remember that the heart requires the best. For peace of mind and efficient operation choose genuine Komatsu fan belts so that your machine will continue to perform at its peak level. The benefits are obvious and results are seen in practice.

References and Further Reading:

1. Komatsu Official Website: Visit the official Komatsu website to access comprehensive information about their machinery, components, and the importance of using genuine parts for optimal performance.

2. Machinery Manuals: Consult your machinery’s operation and maintenance manuals for specific guidance on fan belt selection and care. These manuals often contain valuable insights into maximizing the lifespan and efficiency of your equipment.

3. Industry Publications: Explore industry-specific publications and journals related to heavy machinery and equipment maintenance. These sources frequently feature articles, case studies, and expert opinions on the significance of using genuine components.

4. Online Forums and Communities: Join online forums and communities dedicated to heavy machinery enthusiasts and professionals. Engaging with fellow members can provide valuable insights, experiences, and recommendations regarding fan belt choices and maintenance practices.

5. Machinery Maintenance Courses: Consider enrolling in machinery maintenance courses offered by reputable educational institutions or organizations. These courses often cover the intricacies of equipment components and maintenance best practices.

6. Consultation with Experts: If you have specific questions or concerns about your machinery’s fan belt or maintenance, don’t hesitate to reach out to experts in the field. Consulting with certified technicians or Komatsu representatives can provide personalized guidance and solutions.