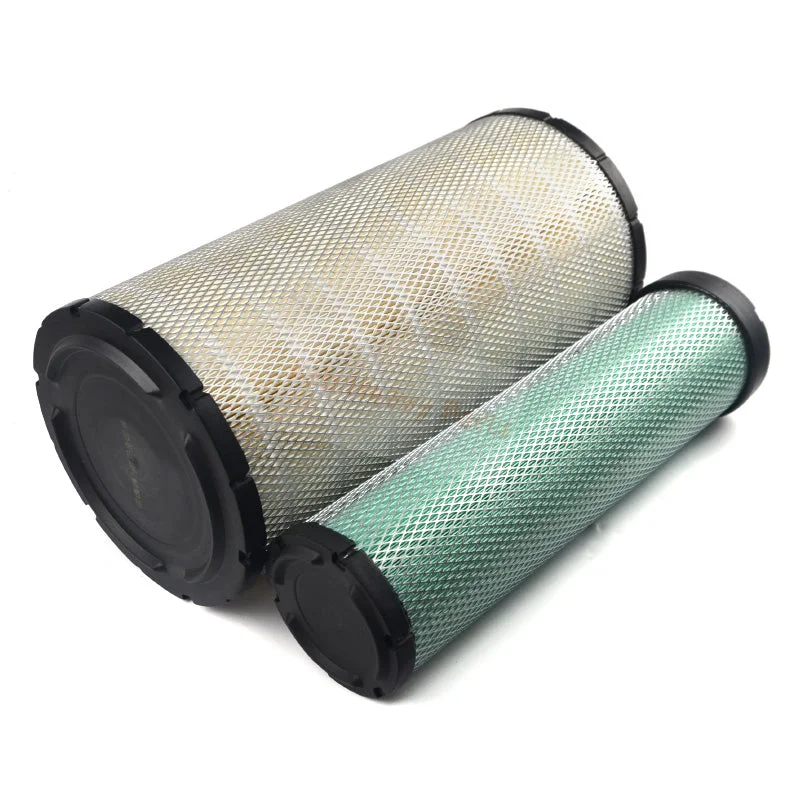

In the sphere of heavy machinery, every part no matter how negligible it may seem plays a key role in the performance and efficiency of the equipment as a whole. Among such items are air filters which are unsung heroes that make sure engines get clean air devoid of impurities and thus improve combustion and reduce wear. The komatsu pc 120 air filter is an outstanding example of precision engineering made especially for komatsu PC 120 machinery.

Air filters are not just screens; they are complexly engineered devices that keep heavy machinery engines operating smoothly and efficiently. This is seen in komatsu pc 120 air filter, which is also representative in terms of design and performance. By acting as the first line defense against dust particles, debris and contaminants in the atmosphere, this filter ensures that Komatsu PC 120 performs at its best even under tough conditions.

The significance of the komatsu pc 120 air filter system will be analyzed in depth within this guide with regard to mechanics, features, and maintenance procedures thereby giving insight into its relevance to broader frameworks regarding heavy equipment operations.

Basics of Air Filter Systems in Heavy Machinery

As simple as air filters might seem to be, they are architectural marvels designed to cope with the heavy-duty requirements of heavy machinery. Their main purpose is to ensure that engines get clean and unpolluted air which is very important for efficient combustion and general machine health. Let’s discuss some basics of how they operate in order to appreciate the unique mechanics behind the komatsu pc 120 air filter system.

How Air Filters Function and Their Significance:

- Filtration Mechanism: At its heart, an air filter does the work of arresting and retaining particulate matter like dust, pollen, and other air contaminants from going into the engine. This can be done using porous material where unwanted particles are captured but it allows airflow.

- Optimizing Combustion: For there to be a successful combustion process within an engine, it needs clean air. Any impurities that are present will interfere with this process resulting in poor combustion efficiency, less output power and high emissions.

- Protecting Engine Components: Dust or debris is abrasive thus by avoiding them from entering into the engine; the filters protect delicate parts from getting damaged hence they extend their lifespan.

- Maintaining Fuel Efficiency: A blocked or poorly performing air filtration system can cause limited airflow thereby making the engine overwork while consuming more fuel. For this reason, filters contribute towards maintaining fuel economy since they make sure that a constant supply of uncontaminated air flows through them.

The Mechanics Behind the Komatsu PC 120 Air Filter System:

- Multi-Layered Filtration: The komatsu pc 120’s air filter uses several layers of filtration. By doing so, even small particles not trapped in a single layer will be caught as they pass through others ensuring thorough filtering has taken place.

- Optimized Airflow Design: In order to achieve optimal filtration alongside maximum airflow capacity, this filter must strike a balance between itself two competing roles. This equilibrium guarantees that without any significant resistance Komatsu PC 120 engine shall receive a continuous flow of clean air.

- Durable Construction: For the air filter, it is made of materials capable of withstanding vibration, temperature changes and exposure to different elements owing to harsh operating conditions in which heavy machinery like Komatsu PC 120 operates.

- Easy Maintenance Design: The komatsu pc 120’s air filter has been designed for easy accessibility and replacement, because they know it is important to maintain filters regularly. This maker-friendly approach allows operators to quickly inspect, clean or replace as per their requirements.

In principle, the komatsu pc 120 air filter system in such heavy machinery is an embodiment of applied engineering. These filters are critical not just for engine health but also for overall machine efficiency and performance.

Key Features of the Komatsu PC 120 Air Filter

The komatsu pc 120 air filter, which is a result of meticulous engineering, has been specially designed to cater for the particular needs of Komatsu PC 120 machine. The design and qualities of it are indicative of the company’s commitment to excellence, productivity and durability. Let us look at the important points that make this air filter unique.

Material Specifications:

- Quality Filtration Media: This advanced material used in making the komatsu pc 120 air filter can ensure that even the very small pollutants are properly filtered off thereby supplying a cleaner gas to an engine

- Strong Frame Construction: The construction of its frame makes it rigid and ensures its durability as well. Such construction helps maintain the shape and form of filters even under tough working conditions.

- Pleat Design: It has increased number of pleats on its surface leading to more efficient filtration without compromising on airflow. This design allows more impurities to be captured by the filter while still permitting free passage of gases into an engine.

- Seal Edges: When it comes to this kind if filters, they have sealed edges which prevent unfiltered air from going through them. Hence such design would see all incoming air pass through their filtration materials only.

Performance Characteristics and Filtration Efficiency:

- High Filtration Efficiency: More than 99 percent of airborne particles are trapped by the komatsu pc 120 air filter- a big reason why it has one of the highest possible efficiency levels compared to others in its class; a feature so crucial for Komatsu PC 120 engines health and performance.

- Optimized Airflow: Despite having high filtration efficiency, this filter is made in such a way that enough space is left for optimum airflow required by an engine when combusting. This gives room for both –cleaning gasses’ mixture within combustion chambers that keep them healthy –their lungs-and ensuring right action under any driving condition.

- Extended Lifespan: Built with strong structures using high-grade materials, this komatsu pc 120 air filter has an extended service life. Hence, it wears at a slower rate and therefore does not need to have the filters on a regular basis thereby saving on costs and reducing down time spent on changing them.

- Resistance to Environmental Factors: Whether in a dusty construction site or humid agricultural fields, the materials used in making this filter are designed in such a way that they can perform under different environmental conditions. This is because its materials and construction make it remain effective irrespective of the external hardenings.

Generally, the komatsu pc 120 air filter blends together innovation, quality material sourcing as well as functional attributes. In so doing, it is able to meet the demands of Komatsu PC 120 machines most times exceeding them by providing clean air and ensuring engine efficiency.

Role of the Air Filter in the Komatsu PC 120

It is a guardian that the engine of Komatsu PC 120 can breathe in clean and free from contamination air. Longevity, efficiency, and overall performance of the machinery depend on its role which is critical. This section will delve deeper into this point in relation to the multifaceted role played by air filter in Komatsu PC 120.

How The Komatsu PC 120 Air Filter Ensures Clean Air Intake:

- First Line Of Defense Against Contaminants: Dust and other particulate matter like pollen are some of the airborne contaminants trapped by komatsu pc 120 air filter. The only thing which goes through to the engine through this filter is clean air after trapping these particles.

- Enhanced Combustion: To have optimum combustion of fuel within the engine, it must have fresh oxygened air. By ensuring a steady supply of uncontaminated air, this filter plays a key role in optimizing fuel combustion process hence better fuel economy and lower emissions.

- Protection against Abrasive Particles: A few airborne particles are harsh materials and if they find themselves inside an engine may cause internal components to wear out fast. As a result, abrasive particles do not go into the engine because of komatsu pc 120’s air filter thereby extending its life span.

The Relationship Between the Air Filter and Engine Performance:

- Engine Health Maintenance: If an air filter becomes clogged or inefficiently functions then it affects various problems within an engine such as reduced power output or increased fuel consumption rate. It helps keep up health state of an engine by allowing consistent flow of pure air to enter it thus maintained with help from komatsu pc 120’s air filter.

- Reducing Operational Costs: Better fuel efficiency due to well-maintained filters leads to less wear on engines as well as fewer maintenance requirements thus contributing towards optimal machine performance and substantial operational savings too.

- Preventing Long-Term Damage: Continuous exposure to contaminants can lead to long-term damage and reduced engine lifespan. Its purpose of Komatsu PC 120’s air filter is to effectively eliminate these contaminants thereby preventing possible future damages in its engine.

- Supporting Other Systems: The running of an engine affects other systems including the hydraulic ones, transmission components, etc. Hence indirectly supporting their functioning, komatsu pc 120 fuel filter allows such units to work optimally.

The komatsu pc 120 air filter is a silent workhorse that tirelessly ensures the Komatsu PC 120 functions at its peak. Though often overlooked, it plays a fundamental role in maintaining the machinery’s longevity, efficiency, and overall performance.

Maintenance and Care for the Komatsu PC 120 Air Filter

Maintaining the longevity and ensuring that the komatsu pc 120 air filter works at its best necessitates regular maintenance. This is like all other parts, the dust filters as they are known commonly are prone to wearing out due to their very important role of removing contaminants. In this paragraph, we shall try and look into some possible ways of taking care of machine so that your filter could serve you adequately.

Regular Inspection and Cleaning Procedures:

- Routine Visual Checks: Once in a month or after engaging in laborious activities in dusty conditions it is good to have a look at Komatsu PC 120 air filter. Ensure that there are no visible signs of damage, dirt accumulation above normal levels or any other noticeable defects.

- Cleaning: If the filter appears dirty but not damaged, it can often be cleaned. Gently clean off the debris by blowing compressed air through it but make sure to blow from inside out so that more dirt does not penetrate deeper instead.

- Seal Inspection: Look for breaks on the seals for any leaks. A seal that has failed will cause unfiltered air to enter an engine making a filter useless.

- Internal Inspection: Some times remove the right side cover and check for debris at its mouth; if dirt is found beyond filter level then maybe there’s a leaking problem with filters or else replacement should be considered.

Tips for Extending Life Expectancy of Komatsu PC 120 Air Filter:

- Do Not Over-Clean: Although maintaining cleanliness of your unit’s filters is paramount, excessive cleaning exposes them to damage which reduces their effectiveness. Therefore, ensure that you adhere to what was provided by Komatsu concerning when you should clean it.

- Reinstall Properly: After checking or cleaning your komatsu pc 120 air cleaner, make sure you re-install it right way around without missing anything proper installation helps prevent unfiltered bypassing airflow.

- Work in Cleaner Areas: Wherever possible work with less polluted environments while using the Komatsu PC 120. This will reduce the load on the filter and prolong its life span.

- Keep Spares: Always have one more new komatsu pc 120 air filter with you; this is in case the existing one gets spoilt or choked up, a spare can be used immediately to replace it reducing downtime.

- Replace as Recommended: Despite good usage, all filters are bound to wear out someday. Keep changing Komatsu’s recommended times in order for your engine to always breathe clean air.

In summary, the maintenance of komatsu pc 120 air cleaner is important since it is an essential part that should not be ignored. The filter continues to protect the Komatsu PC 120 engine through following recommended practices of taking care of it by those responsible thereby realizing high performance and longer life duration.

Troubleshooting Common Issues with the Air Filter System

Like any other part, the komatsu pc 120 air filter can develop issues over time, especially in harsh environments or due to neglect of maintenance. Early recognition and resolution of these problems will help avert bigger ones later on. This article will highlight some common issues associated with air filters and how to fix them.

Recognizing Signs of Clogging and Potential Problems:

- Engine Sluggishness: One of the first indications of a blocked air filter is reduced engine performance. Engine may feel like it’s dragging especially when under load because airflow is restricted.

- Increased Fuel Use: The clogged komatsu pc 120 air filter could cause the combustion to be less efficient leading to an increased fuel consumption. If you notice that your fuel efficiency has suddenly dropped, it is advisable to check whether there are any problems with your air filter.

- Black Smoke or Flames from Exhaust: Lack of enough oxygen for proper combustion causes incomplete burning of fuel that leads to black smoke or flames coming out through exhaust pipe.

- Abnormal Engine Noises: During acceleration, one might hear whistling or choking sounds emerging from the engine which shows difficulty in passing air through a clogged filter.

- Visible Dirt Particles: In many cases, simple visual inspection can reveal if the filter is dirty. A thick coat of dirt covering the outside surface clearly indicates that washing or replacing is necessary.

Solutions and Fixes for Common Air Filter Issues:

- Regular Cleaning Techniques: regular cleaning using compressed air as mentioned before can keep the filter running efficiently. Wash it too much at your own risk since this could destroy its cloth material thereby reducing its life span.

- Get a New One: Damaged, excessively dirtied komatsu pc 120 air filters or those that have seen longer usage periods than recommended should be replaced. Always opt for genuine Komatsu replacements to ensure optimal fit and performance.

- Check For Leaks: If dirt is detected within the intake side or downstream components such as after cooler or turbocharger it may imply the possibility of a filter housing or seal leak. Make sure that the filter is well positioned and all seals are not broken.

- Operational Best Practices: Try minimizing usage of Komatsu PC 120 under too much dust or dirt environments. If this is not possible, increase the number of times you check on air filters and clean them.

- Refer To The Manual: Komatsu PC 120 operator’s manual has information specific to the equipment which may be useful for troubleshooting purposes. In case of recurring problems, one can refer to the manual or get in touch with any Komatsu representative.

Basically, although komatsu pc 120 air filters are meant to last long and function effectively, they experience problems due to exposure to harsh environments. By recognizing these issues at an early stage, Komatsu PC 120 will continue running smoothly thus protecting the engine from damage and ensuring overall efficiency for your machine.

Replacement Tips and Best Practices

The komatsu pc 120 air filter is a consumable component, meaning that over time, even with the best care, it will require replacement. Ensuring that the replacement process is done correctly is crucial to maintain the optimal performance of the Komatsu PC 120 machinery. Here, we’ll delve into when and why to replace the air filter and offer best practices to ensure a smooth replacement process.

When and Why to Replace the Komatsu PC 120 Air Filter:

- Scheduled Replacement: Adhering to Komatsu’s recommended replacement intervals is a proactive approach to maintaining engine health. Regularly scheduled replacements ensure that the filter functions optimally and prevents potential engine issues.

- Visible Damage: If the filter shows signs of tears, holes, or other physical damage, it’s time for a replacement. Damaged filters can’t provide efficient filtration and might allow unfiltered air into the engine.

- Persistent Clogging: Some operating environments are so dusty or dirty that the filter becomes clogged frequently, even with regular cleaning. If you find yourself cleaning the filter excessively, consider replacing it to ensure optimal airflow.

- Performance Issues: If you’ve ruled out other causes and the machinery still shows signs of reduced performance, fuel inefficiency, or unusual engine sounds, it might be time to replace the komatsu pc 120 air filter.

Best Practices for Replacing the Air Filter:

- Use Genuine Komatsu OEM Parts: Always opt for genuine komatsu oem parts when replacing the air filter. These parts are designed specifically for the Komatsu PC 120 and ensure a perfect fit and optimal performance.

- Clean the Housing: Before installing the new filter, clean the air filter housing and the area around it. This prevents any residual dirt or debris from entering the engine with the new filter.

- Ensure Proper Seating: When installing the new filter, ensure it sits properly within its housing. Improper seating can lead to unfiltered air bypassing the filter and entering the engine.

- Check Seals and Gaskets: Ensure that all seals and gaskets are in good condition. Replace any that show signs of wear or damage to ensure an airtight fit.

- Document the Replacement: Keep a record of when the filter was replaced. This helps in scheduling future maintenance and replacements.

- Dispose of the Old Filter Properly: Used air filters can be contaminated with dirt, oil, and other substances. Ensure you dispose of them in accordance with local regulations.

In summary, while the komatsu pc 120 air filter is designed for longevity, there will come a time when it requires replacement. By following the best practices outlined above and ensuring timely replacements, operators can ensure that the Komatsu PC 120 machinery continues to operate at its peak, safeguarding both its performance and longevity.

In the world of heavy machinery like the Komatsu PC 120, even the smallest components play a crucial role in ensuring optimal performance. The komatsu pc 120 air filter, often overlooked but undeniably vital, exemplifies this principle. This comprehensive guide has explored the mechanics of the air filter system, its key features, its role in the Komatsu PC 120, maintenance practices, troubleshooting tips, and replacement best practices.

As we conclude, it’s essential to underscore the pivotal role that the komatsu pc 120 air filter plays in safeguarding the engine’s health and the machinery’s overall performance. Its ability to filter out contaminants, ensure clean air intake, optimize fuel combustion, and protect against engine wear is indispensable.

Regular maintenance, including routine inspection, cleaning, and timely replacement, is the key to ensuring that the air filter continues to serve its purpose efficiently. By following the best practices outlined in this guide and adhering to Komatsu’s recommended maintenance schedules, operators can maximize the lifespan of their machinery and minimize downtime.

In a world where heavy machinery operates in diverse and often challenging environments, every component, no matter how seemingly small, contributes to the larger goal of operational excellence. The komatsu pc 120 air filter, with its design, features, and maintenance requirements, is a testament to the commitment to quality and performance in the Komatsu machinery lineup.

In conclusion, the diligent care and maintenance of the komatsu pc 120 air filter ensure that the Komatsu PC 120 machinery operates at its best, meeting the demands of various industries and contributing to the success of countless projects.

References and Further Reading

- Komatsu PC 120 Operator Manual

- Komatsu Genuine Parts Brochure

- “The Importance of Air Filters in Heavy Machinery” – Industrial Equipment Magazine

- “Maintenance Practices for Heavy Machinery” – Construction Equipment Journal

- “Optimizing Fuel Efficiency in Heavy Equipment” – Engineering in Construction

- “Air Filter Replacement Best Practices” – Heavy Machinery Maintenance Guide