When it comes to heavy machinery and construction equipment, nothing but precision and reliability matter a lot. Each part of the machine plays a vital role in ensuring that these hulking machines operate well. One of the many parts that make up these mechanical giants is the final drive. In this guide, we will delve into Komatsu final drive parts, focusing on their importance in Komatsu machineries.

1.The Backbone of Heavy Equipment: At the center of every Komatsu heavy machine is its complex system called final drive which converts power from an engine into torque used for moving or operating it. The strongest machinery ever built may be brought down due to poor condition or technical failure of the final drive. This significance highlights why Komatsu final drive parts are necessary.

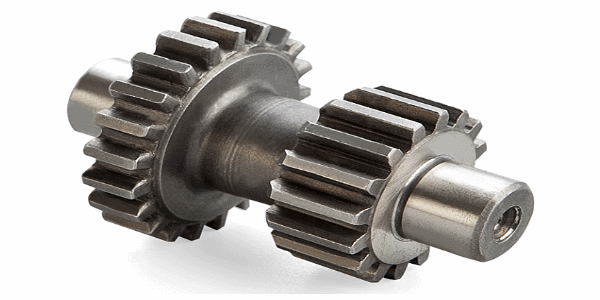

2.A Complex Ensemble: These many individual subsidiary components serve different purposes in the final drive system. These constituents range from gears and bearings, through seals to housings which work together harmoniously facilitating smooth running as well as efficiency of such machines. It is crucial to know each component’s function so as to appreciate the importance selecting appropriately and taking care of them.

3.The Goal of this Guide: In this guide then, we will cover various aspects of Komatsu final drive parts right from understanding components making up a complete system for your machine’s final drive down to choosing what fits your machine best as well as maintenance practices and troubleshooting tips so that you can keep your Komatsu machinery at peak performance.

As we venture into the world of Komatsu final drive parts, it is important to realize that rather than being simply cogs in a wheel; they form bloodline around any heavy equipment. Thereby, without proper selection or maintenance there can be no longevity, reliability and efficiency associated with owning any piece of Komatsu machinery. So let us swim through details about our intricate friends who are both strong and precise –final drive spare parts from where we shall emerge wiser than before.

Understanding the Components of Komatsu Final Drive

In order to understand the significance of Komatsu Final Drive Parts, it is important to get into the intricate world of the system’s components. In heavy-duty machinery, final drive refers to a complex assembly of parts. Each part has its own role and importance as far as smooth functioning of heavy machinery is concerned. Let’s have a look at these components in order to get a better understanding of their role.

1.Gears: The gears are at the center of the final drive system. These pieces of engineering transmit power from an engine to wheels or tracks that move heavy equipment. This arrangement determines the direction and speed at which machine moves. Gearing in this final drive must be designed meticulously and manufactured precisely so as not to break under massive forces and torque generated by heavy machinery.

2.Bearings: Bearings are actually unsung heroes in this final drive system. They reduce friction and ensure that movement on hinges is carried out smoothly. In the context of final drive parts, bearings support gears and shafts enabling them to rotate with minimum resistance. Good quality bearings will prevent them from wearing out too fast so that they last for long periods.

3.Seals: Seals play an important role in keeping off contaminants such as dust, dirt, water etc from entering into the final drive housing. They stop anything that may damage internal elements from getting into this system thereby maintaining its integrity through proper sealing.

4.Housing: The housing for the final drive is nothing but a shell covering all other inner components together with it; it supports metaphysically this case for gearsets and bearings being lubricated correctly aligned; it should be durable enough because working conditions can be very rigorous.

5.Shafts and Axles: Shafts as well as axles perform function shifting rotational motion from gears to wheels or tracks on machines involved during work processes where huge force is used here they have significant influence as they change input energy into mechanic movement.

6.Lubrication System: To minimize friction, dissipate heat and make the machine run smoothly, a well-designed lubrication system is what the final drive depends on. Components must be properly lubricated to avoid overheating and premature wear.

7.Fasteners and Bolts: These are fundamental components in the final drive which are normally ignored by many people. Fastener should be of high quality and suitably torqued to prevent loosening or breakage during operation of heavy machinery.

It is important that equipment owners and operators understand how these components work together within the final drive system. The performance, long service life, and reliability of Komatsu machinery depend on the quality, compatibility as well as maintenance of these components.

Selection of Komatsu Final Drive Parts

Choosing the appropriate Komatsu Final Drive Parts is an important decision that directly impacts on heavy machinery’s performance and lifespan. Selecting correct components make certain that final drive systems function at top notch efficiency, which is critical for overall productivity of equipment. Here are important factors to consider when making your choice:

1.Compatibility: When buying final drive parts, compatibility should be the first and foremost consideration. Ensure that components selected are meant for the specific model of your Komatsu machinery. Each model of Komatsu may have unique specifications, thus using inaccurate fitting can bring about performance problems and even damage.

2.Quality and Authenticity: Choose original Komatsu final drive parts. Genuine parts have been designed for best fit to maintain high quality standards set by the manufacturer in addition to their reliability. They also work perfectly with other Komatsu parts hence ensuring equipment originality.

3.Warranty: Normally, genuine Komatsu parts come with warranty cover that offers protection against defects as well as malfunctions thereby reducing risk on financials occurring during replacement of spares.

4.Longevity: High-quality Komatsu final drive parts are built to last long. Their structure is made up of strong materials and they undergo rigorous testing processes in order to withstand harsh working conditions within heavy machines environment. Investing in long lasting units can reduce downtime and maintenance costs over time too.

5.Performance: Genuine Komatsu parts are crafted to enhance performance levels of your equipment. They enable an efficient final drive system hence enough power supply and torque needed for various applications under heavy loads’ conditions ultimately leading to higher fuel efficiency as well as productivity gains.

6.Resale Value: The use of original spare parts from manufacturer such as genuine Komatsu final drive parts can increase resale value of such machine brands. Authenticity plus quality counts much whenever anybody wants to buy or replace his/her machine therefore it’s beneficial when anyone uses majorly this kind of stuff while selling off his/her machinery in the near future.

7.Expert Advice: In case you are uncertain about the final drive parts to choose or you have specific operational requirements, consider consulting with Komatsu experts or authorized dealers. They can provide helpful insights and recommendations that match your specifications.

8.Cost-Effectiveness: Though genuine Komatsu spares might be expensive than aftermarket alternatives at the beginning, they may turn out to be cost-effective in long run. Their durability and performance result into limited breakdowns, less frequent replacements as well as lower maintenance costs in general.

Therefore, when selecting Komatsu final drive parts, it is important to prioritize compatibility, quality and authenticity. By using appropriate components in your heavy machine you will ensure that it operates optimally with consistent performance as well as efficiency.

Benefits of Using Genuine Komatsu Final Drive Parts

When dealing with heavy machinery and its proper operation and efficiency, the choice of final drive parts is crucial. The use of Komatsu genuine final drive parts among other things promotes their productivity, durability, reliability and cost effectiveness to mention but a few for example:

1.Reliability and Durability: Genuine Komatsu final drive parts are specifically designed to meet the manufacturer’s strict quality requirements, given that they are subjected to rigorous testing ascertaining their ability to withstand harsh conditions in which heavy machinery operates. Consequently, this means that they are reliable translating into lower downtime levels leading to increased productivity.

2.Precise Fit: Genuine parts are engineered to fit snugly into your specific model of Komatsu machine so as a result the rest of your machine will not be compromised due to one component that is out of place in your final drive system as it fits together seamlessly with all other components within that system; there will be no problem regarding compatibility unlike when you use fake parts.

3.Compatibility: When you decide on genuine Komatsu final drive parts it means these components can get along well with other products from the same company which is useful for smooth running of your equipment thereby avoiding mismatching components hence performance issues or damages.

4.Warranty Protection: On top of that, real Komatsu spare parts normally have warranties covering replacement due to faulty functions for instance. Such warranty provisions would go a long way in giving assurance to owners of such equipment who otherwise would always be at risk whenever they need spares.

5.Longevity: For instance, original Komatsu pieces last long because they’re made up durable materials capable of surviving tough environments like construction sites or mines where the machines work under pressure most times; thus providing for an extended service life span.

6.Optimal Performance: This involves design and manufacture by engineers at Komatsu company so that those particular items they make will function best in them through power delivery system consisting necessary torque and speed for any standard heavy duty application. These genuine final drive parts enable your machine to run efficiently thus saving on fuel consumption as well as increasing productivity.

7.Reduced Maintenance Costs: Although, initially genuine parts may seem costly compared to the aftermarket ones, they have proven to be cost effective over time since they are durable and do not break down easily thus reducing emergency replacements as well as maintenance bills.

8.Resale Value: The apple of the buyers’ eye is machines which have used original Komatsu final drive products and maintained them all along with high quality components when it’s time to sell or trade in such equipment. Buyers tend to value equipment that has been cared for with original top-quality components.

In summary, there are several advantages of using real Komatsu final drive spares beyond improving its operation right away. These include reliability, compatibility, warranty cover, durability and cost effectiveness; hence by going for genuine parts an owner can guarantee maximum productivity from their machinery even in most challenging grounds ever met by any plant with similar features.

Maintenance and Care for Komatsu Final Drive Parts

To make sure your Komatsu final drive parts last long and function optimally, they should be maintained well. Failure to maintain it can lead to premature wear and expensive repairs. Below is a detailed guide on how to maintain and take care of your Komatsu final drive components.

1.Regular Inspection: Be frequently looking at these final drive parts for signs of wear, damage or loose connections. There should be no leaks, cracks or any strange noises while using the machine. Catching such issues early will prevent major ones.

2.Lubrication: Proper lubrication is essential for the smooth operation of the final drive component(s). Stick with the manufacturer’s instructions regarding lubrication intervals as well as their recommended lubricants. Make sure no grease or oil is applied without cleaning out the lubrication points first.

3.Cleaning: Keep your final drive parts clean from mud, dirt, and debris at all times using a pressure washer or steam cleaner to get rid of caked on dirt. Dirt accumulation results in high friction levels which in turn cause wear prematurely.

4.Tension and Alignment: Regularly check if the tension and alignment of the final drive components are correct and order them if necessary Misalignment can cause uneven wear reducing efficiency.

5.Temperature Monitoring: Monitor temperatures associated with your final drive parts during operation Overheating may indicate problems with lubrication or excessive friction Promptly address overheating problems to avoid damages

6.Seal Inspection: Inspect that there are no leaks from seals on your final drive components Faulty seals allow dirt into the system causing faster aging hence poor performance Replace damaged seals whenever necessary

7.Preventive Replacement: Consider putting together a program that recommends preemptive parts replacement for items like bearings, belts, and seals This will help avoid sudden breakdowns by replacing them before they fail

8.Professional Service: When unsure about an issue, especially complex maintenance tasks consider seeking help from experts or taking your machinery to the Komatsu service center. They are better placed to diagnose and sort out such issues effectively since they have the necessary expertise as well as equipment.

9.Record Keeping: Keep records of all maintenance activities including inspection dates, parts replacements and repairs This may help you keep track of your final drive part’s condition and plan for future maintenance.

10.Use Genuine Parts: When replacing final drive components, always use genuine Komatsu parts because only genuine parts meet manufacturer’s specifications giving unsurpassed performance and durability

In order to accomplish this you need to inspect them regularly, sometimes even on a daily basis in accordance with this manual and also maintain them at their best possible levels. Regular inspections as well as timely maintenance can prevent expensive breakdowns ensuring maximum returns from investment in equipment

Common Issues and Troubleshooting for Final Drive Parts

Given the fact that final drive parts are serviced regularly, issues can intermittently come up. Identifying common problems and their troubleshooting is vital for minimizing downtime and keeping your heavy machinery running smoothly. Some of the common issues with Komatsu final drive parts and their troubleshooting steps are listed below:

1.Excessive Noise:

- Issue: Unusual noises like grinding, squeaking or knocking may be indicators of some problems within the final drive.

- Troubleshooting: Check for loose bolts, worn gears or bearings. Inspect the components for signs of wear or damage and replace where necessary. Make sure to lubricate properly.

2.Leakage of Fluids:

- Issue: Whether it’s hydraulic oil or gear oil, fluid leaks could affect performance negatively and cause damage.

- Troubleshooting: Identify where the leak is coming from as well as how severe it is. Tighten any connections that are loose, replace any damaged seals or gaskets and refill to recommended levels.

3.Overheating:

- Issue: Final drives overheating could imply lack of lubrication or excessive friction in them.

- Troubleshooting: Inspect fluid levels and quality; make sure adequate lubrication exists in final drive free from debris; look out for misalignment as well as worn-out components which might cause excessive friction.

4.Reduced Power/Efficiency:

- Issue : This results from various reasons such as worn-out components or improper alignment

- Troubleshooting : Conduct a thorough investigation into belts, chains, gears and bearingings . Change all worn out parts . Ensure proper tensioning plus aligning of components .

5.Vibrations/Wobbling :

- Issue : Vibrations/wobbling during operation can show imbalance/misalignment .

- Troubleshooting : Balance any imbalanced components ensuring correct alignment . Fasten all bolts/connections which have become loose . Look out for damages on gears/sprockets .

6.Loss Of Traction :

- Issue : A breakdown in the final drive system could be responsible for loss of traction on your heavy machinery.

- Troubleshooting : Check worn out drive components including gears, sprockets and chains. Replace any worn parts and ensure proper tensioning plus aligning.

7.Reduced Speed :

- Issue : A reduction in speed can be attributed to problems with the final drive system of your equipment.

- Troubleshooting : Examine belts, chains and gears for damages or signs of wear. Make sure correct tension is in place as well as alignment . Oil parts where necessary .

8.Excessive Wear And Tear :

- Issue : Negligence to maintenance practices may cause premature wear and tear .

- Troubleshooting: Look over your maintenance records to see that you have been conducting routine inspections as required also following lubrication schedules. Check for worn parts then make adjustments accordingly.

9.Sudden Loss Of Power :

- Issue : The occurrence of a sudden loss of power might be disturbing, possibly indicating a major problem in the final drive system.

- Troubleshooting: Inspect damaged or broken parts such as belts, chains etc . Examine loose connections while carrying out a comprehensive test on the system .

10.Unresponsive Controls:

- Issue : This may mean that there are issues concerning hydraulic systems/Electrical components within the final drive .

- Troubleshooting: Inspect hydraulic lines/valves and electrical connections . Change all spoilt pieces putting them back into working conditions .

It is important that any malfunctions are addressed promptly so as not to cause further damage while maintaining the performance of Komatsu Final Drive Parts. For more complex or chronic issues, consider seeking help from professional personnel or contacting Komatsu service center for proper diagnostic procedures. Consistent maintenance combined with a thorough troubleshooting process will always keep your heavy machines’ operation smooth and effective.

In the world of heavy machinery, where performance, reliability and uptime are paramount, the selection and maintenance of Komatsu final drive parts play a pivotal role. This comprehensive guide has shed light on the significance of making informed choices and adhering to diligent maintenance practices. Let’s summarize the value of these actions:

1.Optimal Performance: Final drive is the powerhouse for heavy equipment where all components must work seamlessly in order to deliver peak performance. By selecting real Komatsu final drive parts, you guarantee that your machines will be at their utmost giving power efficiency to satisfy challenging tasks.

2.Durability and Longevity: Real Komatsu parts are made tough enough for any environment with unmatched durability. They are built to last hence minimizing replacement frequency as well as reducing downtime.

3.Compatibility and Quality Assurance: These precision-engineered parts fit perfectly into your equipment; they are genuine Komatsu final drive parts. Ensuring that only genuine spare parts are used reduces chances of encountering compatibility issues common with aftermarket or non-genuine components.

4.Cost Efficiency: While it may seem like a small amount more when buying original products at first, it pays off in the long run since these final drives have longer life spans than others resulting in lower costs of maintaining them unlike their counterparts that break down unexpectedly.

5.Reduced Downtime: Incurring downtime can be a huge cost for owners of heavy machinery. You minimize risks of unexpected stoppages as well as expensive repairs by acquiring high-quality components and following strict maintenance schedules.

6.Safety: For equipment operators and those near heavy machinery such as this, reliable final drive parts help maintain safety standards at work places by reducing accidents caused by malfunctioning systems or breakdowns which could have been avoided through use of OEM spares.

7.Resale Value:If in future you wish to sell or upgrade your construction equipment having properly maintained a final drive system having original Komatsu parts can increase its resale value greatly.

In conclusion, the importance of right choice and maintenance of Komatsu final drive parts cannot be emphasized enough. This is an investment into the long-term performance, durability and safety of your heavy machinery. By choosing genuine Komatsu parts and following a preemptive maintenance program you not only maximize the efficiency of your machine but also secure its reliability and worth for coming years. Prioritizing the health of your final drive system is a smart choice for both your business’s bottom line and the safety of your team.

References and Further Reading:

1. Komatsu Official Website: https://www.komatsu.com/

2. Machinery Lubrication: https://www.machinerylubrication.com/

3. Equipment World: https://www.equipmentworld.com/

4. Construction Equipment: https://www.constructionequipment.com/

5. Heavy Equipment Forums: https://www.heavyequipmentforums.com/

6. Komatsu Genuine Parts: The Right Choice Brochure: https://mining.komatsu/en/solutions/parts-service/genuine-parts

7. Machinery Maintenance and Reliability Best Practices by R. Keith Mobley: A comprehensive book that provides insights into machinery maintenance and reliability best practices.