In the world of heavy machinery, each part has a role to play in order for the machine to function well and continue working over an extended period. One of such components is final drive parts which are often considered as the heart of any machinery. It is because they facilitate movement and efficient running of the machine by transmitting power from the engine to wheels. In this range of products, some komatsu final drive parts have proved their worth in terms of being durable, accurate and first-class.

Komatsu has always been a leader in its line of business as far as quality and innovation are concerned; this trend had taken place for many years. The same applies to komatsu final drive parts. These allow the Komatsu fleet that ensures that all machines deliver on performance and reliability as per their brands promise. Whether it is an excavator, bulldozer or any other heavy-duty equipment, these final drive parts from Komatsu are meant to withstand tough field conditions while giving long life with less maintenance requirements.

Understanding the Final Drive Mechanism

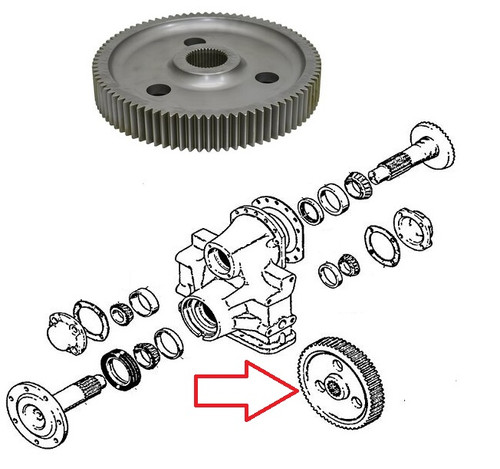

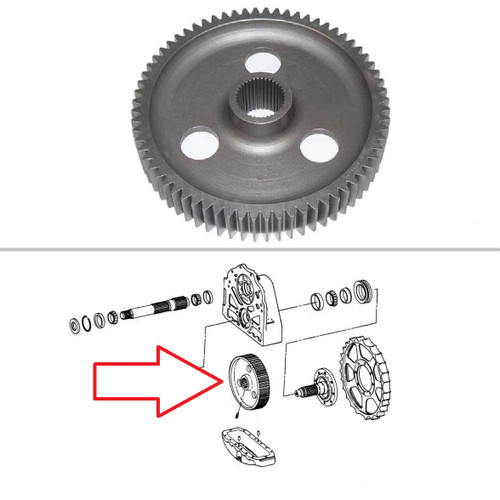

In heavy machinery, the final drive bridge is an important part that links an engine with its wheels or tracks. Its main job to allow the creation of motion ability to transmit power from the engine to other parts of a machine in order for it to operate and move as intended. If there were no operational final drive system, then the whole machine would be immobile thus indicating its significance in this system.

The core of the final drive mechanism involves some gears and shafts put together to control the flow speed and torque that is transmitted onto wheels or tracks. This regulation ensures that machines can adapt themselves into different terrains and loads so as not to overstrain the engine.

Talking about komatsu final drive parts means mentioning about a range of components specifically made for use with Komatsu’s heavyweight equipment line. They are not just copies but rather they are designed by experts who know what they are doing in order to maintain high quality and performance levels associated with this brand name. Thus, incorporating these parts will ensure smooth power transmission enhancing lower tear on engines thereby maintaining top operating standards of the final drive mechanism.

Ultimately speaking, although final drives systems applies universally in heavy duty machinery, komatsu final drive parts stands out with specialization and distinction. They are designed towards meeting specifications unique for Komatsu product hence ensuring perfect coordination between them and other components of this mechanical systems which guarantees peak performances all through.

Key Specifications of Komatsu Final Drive Parts

The heavy machinery industry is one where small things can really make the difference. The output performance, efficiency and longevity of a machine are largely determined by the kind of components used in it. These quality final drives are designed with specific features and specifications for compatibility with Komatsu’s high standards.

Components And Features Detailed Breakdown:

- Quality Of Material: One of the most noticeable things about the komatsu final drive parts is that they use better materials. Such parts can be made from high strength steel alloys, hence; durability, wear resistance as well as long life.

- Gear Design: The gears in the final drive parts are engineered to ensure smooth power transmission. They have helical designs that decrease noise and vibration levels thereby increasing equipment’s efficiency.

- Integrity Of Seal: For its final drive parts, Komatsu attaches great importance to seal quality. Thus, these seals protect against dirt or water entering the internal body areas and lubrication systems that keep them safe.

- Bearings Quality: Komatsu uses very strong bearings on its final drive parts for reducing friction during operation and carrying large loads at any given point in time. This design enables it to function properly even when subjected to severe conditions.

- Torque Capacity: Because of their heavy duty nature, Final Drive Parts manufactured by Komatsu have been built with a mind towards being able to handle high torque levels. In this regard, such equipment may therefore operate in challenging terrains without sacrificing its functions.

Understanding Each Specification Importance:

All specifications play a significant role in ensuring proper workability of komatsu final drive parts:

Material Quality guarantees longer lifespan which means less need for frequent replacement during daily operations.

Gear Design influences efficient power transfer – smoothly operating machinery that provides optimal results within required timelines.

Seal Integrity lowers maintenance costs resulting from reduced breakdowns and extends useful life of components involved.

Bearing Quality allows smoother running machines meaning reduced need for component replacement through worn out bearings

Torque Capacity makes it possible to perform heavy-duty jobs without any failures.

In conclusion, they are not just numbers on a sheet of paper but the specifications embodied in Komatsu’s final drive parts. They give evidence of the company’s dedication to quality, performance and dependability. Thus, each specification is carefully considered and designed so that it will ensure that Komatsu machinery is always at its best every day all year round.

Benefits of Using Komatsu Final Drive Parts

Choice of components for heavy machinery can significantly impact their performance, efficiency, and longevity. In the market, there are a lot of options to choose from but choosing genuine parts especially from reputable manufacturers such as Komatsu has numerous advantages. Let us look at the benefits of using komatsu final drive parts which differentiate them from other alternatives.

Advantages of Using Komatsu OEM Parts:

- Better Quality: One main advantage of selecting komatsu final drive parts is that it ensures quality. They are made by the company with a long experience in this industry hence they are manufactured to meet top standards using best materials and precise engineering.

- Top Performance: Genuine Komatsu items fit into machines perfectly ensuring seamless operations. This implies that machines can deliver their optimal performance without any disturbances

- Durability: Komatsu final drive parts are built to last since they have been constructed with better materials and superior design. Consequently, these machines can work longer before needing replacements done thus reducing costs.

- Reasonable Price: While original komatsu parts may seem expensive initially, they provide a better value in the long run. Endurance as well as flawless performance means less damages; therefore lower charges for repair and maintenance plus infrequent replacement intervals.

- Guarantee Plus Assistance: On its OEM products, Komatsu gives an excellent warranty and after-sales support services making its network available any time customers need them in case they encounter problems or defects.

Improving Durability And Efficiency With Real Komatus Parts:

Using genuine komatsu final drive parts does not only ensure that a machine operates at an optimum level but also increases its lifespan. However, aftermarket alternatives which are usually cheaper might not necessarily match exactly what has been indicated by Komatsus requirements and specifications leading to compatibility issues accelerating wearing out which results to inefficiencies.

Conversely, Mitsubishi Final Drives components have been created so as to ensure that every single part works effectively with other elements thereby making them be on top condition always. This helps to minimize pressure on the equipment that in turn helps it to remain efficient and operational for a longer period.

In conclusion, there are many choices available out there but going for komatsu final drive parts has a lot of advantages that highly influence performance, efficiency and life expectancy. It is an investment into trust, quality and peace of mind.

Installation Tips for Komatsu Final Drive Parts

Correct installation of the komatsu final drive parts is important for its durability and optimum performance. This process may appear to be simple, but some steps and precautions need to be taken into account in order to avoid making common mistakes. Below is a step-by-step guide to installing komatsu final drive parts, together with a few relevant best practices.

Step-by-Step Guide on How to Install Komatsu Final Drive Parts:

- Preparation: Ensure that the equipment is stable and turned off before starting the installation process. Also, it is important that you put on safety gear like gloves and goggles to avoid any injuries.

- Clean the Area: The area where these new komatsu final drive parts are going to be fixed must be cleaned first before they can fit well. Take away all dirt or dust and any old lubricants so as not to affect the proper functioning of these new components.

- Inspect New Parts: Before getting them installed, examine them closely for any visible defects or damages. Confirm also that they are up-to-date with the specifications of your machine and that they are genuine Komatsu parts.

- Follow The Manual: Always refer back to your machine’s user manual or else follow an installation guide from manufacturers of such komatsu final drive parts installed. Here you will find detailed instructions tailored specifically for your model number of machinery.

- Lubricate: They should have been properly oiled before being fitted; ensure this happens always. Use only recommended lubricant as indicated by Komatsu so as reduce friction and ensure smooth operation even after their installment.

- Fit the Parts: Place carefully into position those komatsu final drive parts at which they belong; make sure that there is no movement at all while ensuring that it fits perfectly without any force required, which could damage both part itself or machinery at large.

- Secure the Parts: You can then secure them using proper bolts/fasteners once everything has been fitted correctly in place. To avoid any malfunctioning during operation, ensure that they are tightened up to the torque settings specified.

- Test the Machinery: After installing, turn on the machinery and check if it works. Listen for any unusual noises and make sure the machine moves without any hitch. If there are any issues, go back to installation.

Common Mistakes to Avoid:

- Using Non-Recommended Lubricants: Komatsu lubricants should always be used; others may interfere with smooth operations of the parts.

- Over-Tightening: Do not overdo tightening of bolts or fasteners though one should still secure them well. This can lead to wearing out of those parts prematurely due to stress caused by such excessive efforts.

- Skipping the Manual: Do not depend on experience only; remember manual is necessary when you want to install koratsu final drive parts right in your type of model.

In conclusion, while installing komatsu final drive parts might seem like a routine task, paying attention to the details and following best practices can significantly impact the performance and lifespan of the machinery. Proper installation ensures that machines run efficiently thus reducing their breakdowns and increasing their lifespan.

Maintenance and Care Recommendations

It is crucial to maintain and take care of komatsu ultimate drive parts if they are to last long and function optimally. Though these parts have been built for durability, regular checks and maintenance can prolong their life span tremendously and keep the machine working smoothly. Below are some routine checks and maintenance tasks done on komatsu final drive parts.

Routine Checks:

- Look: Visually examine frequently komatsu final drive parts to determine whether there is any wear, destruction or leakage that one can see with bare eyes. It includes cracks, broken seals or signs of corrosion. Early discovery of these issues prevents the occurrence of bigger problems in the future.

- Monitor Oil Levels: One should always ensure that oil levels are within a recommended range where low amounts could imply an increased friction as well as wearing out thereby reducing efficiency and lifespan of the components.

- Seal Inspection: Regular inspection of seals for damages or any forms of destruction will aid in preventing foreign materials from getting into your final drive.

- Bearing Checks: Good bearing ensures smooth operations. Unusual sounds do indicate worn out bearings. Replace them accordingly.

- Gear Check: There should be periodic gear inspections for wear and tear signs present in them which must be devoid of debris before they interlock properly.

Maintenance Procedures:

- Keep Clean Regularly: These parts require periodical removals so that unnecessary particles such as dirt, debris or pollutants can be eliminated from them. In addition to making sure things work smoothly, this enhances visual examination too.

- Lubricate Often: Regularly lubricate the components using correct oils prescribed therefore lowering friction hence ensuring smooth performance as well as minimal wearing processes involved here.

- Replace Worn-Out Parts: Any part exhibiting excessive wearing off or damage must always be replaced promptly because using such worn-out ones might strain machinery lowering its productivity level.

- Seal Renewals: If you observe any damages on the seals or they look aged then it is time for replacements so that internal objects remain untouched.

- Calibration On A Regular Basis: Calibrate the final drive parts of komatsu frequently. This guarantees that they run at their highest efficiency and decreases the likelihood of equipment malfunctioning.

Tips on Longevity and Optimal Performance:

- Use Original Komatsu Parts: Always go for genuine komatsu final drives when buying replacements. This will ensure compatibility and maintain machine performance.

- Don’t Overload: The komatsu final drives should not be overloaded above their capacities. Overloading may strain them hence reducing their lifespan in return.

- Periodic Training: Ensure that operators are trained regularly as well as updated with any pertinent information about best practices. Proper operation can significantly reduce the wear and tear on the parts.

While komatsu ultimate drive parts are built for durability, regular maintenance and care can greatly extend their lifespan as well enhance efficient operations. Being proactive can save you from future possible problems thus making sure it runs for longer durations without breakdowns or inefficiencies.

Troubleshooting Common Issues with Final Drive Parts

Even with care, maintenance and meticulousness, machinery can still occasionally come up for problems. Understanding common problems which may arise in komatsu final drive parts is crucial since it not only reduces downtime but also enhances operational efficiency. This is a guide to some of the troubleshooting prevalent issues emanating from these parts.

Common Issues and Solutions:

Unusual Noises Experienced During Operation:

- Cause: Worn-out or damaged bearings.

- Solution: Inspect these bearings and replace them if necessary. Ensure adequate lubrication to prevent future wearing.

Leakage of Lubricant:

- Cause: Damaged seals or overfilled lubricants.

- Solution: Check the seals for any signs of damage and change them if required. Make sure that the amount of lubricant is within normal range.

Reduced Power Transmission:

- Cause: Worn gears or torque converter problems

- Solution: Inspect gears for wear and tear, then replace any worn ones where necessary. Examine the torque converter for malfunctions and address appropriately.

Overheating of the Final Drive:

- Cause: Low levels of lubricants; wrong oil used

- Solution: Monitor oil levels adding more if need be. Ensure usage of right recommended oil type.

Vibrations during Operation:

- Cause:Misaligned or damaged gears

- Solution: Examine gears for defects while aligning them correctly afterward .Replace all broken components.

Difficulty Shifting or Movement:

- Cause: Problems with hydraulic system; final drive component faults

- Solution: Investigate malfunctioning hydraulic systems. Scrutinize whether there are broken komatsu final drive parts that need replacement,

Diagnostic Steps include:

Visual Inspection:Before delving into comprehensive troubleshooting, always begin by visually inspecting equipment.Checks for any visible evidence such as cracks, wears or leaks should be done at this stage. Operational Test– Run the machine to observe operations. Look out for unusual sounds, feel vibrations if present & consider any abnormalities within its moving pattern. Refer to the Manual:Most machinery manuals have a troubleshooting section specific to the model. They can give an idea of what might be wrong. Seek Expert Assistance, If the problem persists after initial troubleshooting efforts, consulting a qualified technician or specialist may be helpful. They will carry out more extensive diagnosis and suggest possible remedies.

In conclusion, although designed for durability and performance, there may still be some challenges with komatsu final drive parts from time to time. This knowledge is invaluable in ensuring continued operation and effectiveness of such machines as well as preventing possible breakdowns from minor into major issues through regular checks and proactive trouble-shooting.

In the complex world of heavy machinery, the importance of each part can never be overstated. The examples of such parts are Komatsu drive items which show how dedicated the company is to superiority, exactness and performance. Although these parts may seem like small components in a large machine, they play an essential role in ensuring that Komatsu machines deliver on its brand promise of reliability and efficiency.

Using genuine komatsu final drive parts is not just an option but also a smart investment in the future of the equipment. These components being crafted with great attention to detail up to superior standards guarantees optimal operation thus reducing downtime so that it performs at its peak. Additionally, if properly installed, maintained and cared for, these parts can significantly prolong operating life of equipment giving you unmatched value.

As a result of flooding markets with alternatives quality and authenticity should become a priority. After going through complexities surrounding final drive mechanism: specifications, benefits, installation tips, maintenance recommendations, and troubleshooting insights, one message remains clear; always go for genuine komatsu final drive parts when it comes to sourcing for such components. It is about choosing what works well today for best performance across all machines now and for days ahead.

References and Further Reading:

- Komatsu Official Manuals: Komatsu’s official manuals provide detailed specifications, installation guides, and maintenance procedures tailored for each machinery model. They are invaluable resources for technicians and machinery owners alike.

- “Heavy Machinery Mechanics: A Comprehensive Guide” by James T. Henderson: This book offers a deep dive into the mechanics of heavy machinery, including detailed sections on final drive components and their significance.

- “The Evolution of Construction Equipment” by Martin L. Roberts: Gain insights into the evolution of heavy machinery and the role of brands like Komatsu in shaping the industry.

- International Journal of Heavy Machinery: A peer-reviewed journal that publishes research articles, case studies, and reviews related to heavy machinery, its components, and industry trends.

- Komatsu’s Official Website: Regularly updated with product launches, technical bulletins, and industry news, Komatsu’s official website is a treasure trove of information for enthusiasts and professionals.

- “Final Drive Systems: Design and Maintenance” by Dr. Alan P. Turner: A technical book that delves into the intricacies of final drive systems, offering insights into their design, function, and maintenance.

- Heavy Equipment Forums: Online forums where professionals, technicians, and enthusiasts discuss various topics related to heavy machinery, including issues, solutions, and experiences with different brands and components.